A Day in the Winery

Specific Events

Putting on a batch: This involves acquiring fruit (a 5 hour round trip to Saskatoon freezers), thawing and crushing fruit, adding amendments according to tests and allowing maceration to occur. At this time we also do tests to determine the timing of pressing and what yeasts and additions will be used. And, of course, ongoing washing and sanitizing of all equipment used and surfaces touched.

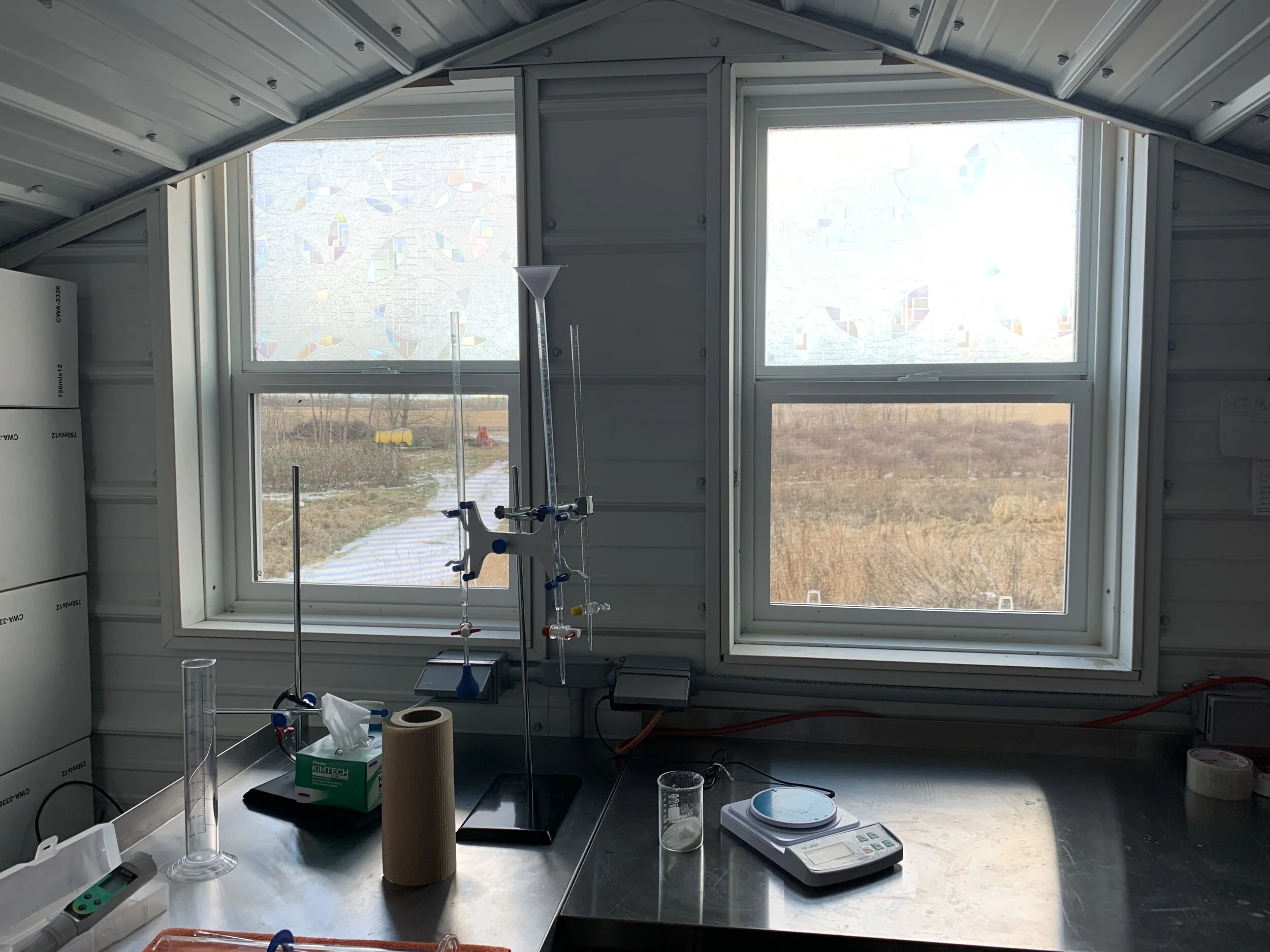

Monitoring an active ferment: If there is an active ferment underway, the Winemaker or assistant may be punching down, stirring, testing for Brix and acidity, assessing aromas and flavours, deciding to rack or filter, blend or prepare for bottling.

Racking/pumping from tank to tank: This process occurs after ferment is complete, following rough filtering and/or fining, or any time lees are deemed to be excessive. It will also be done during bottling.

Monthly sanitation regimen: This is done according to a pre-determined list close to the 20th of the month, and takes about 4-6 hours for one person; two people can complete it in about 3 hours. It takes longer in summer due to dust prevalence.

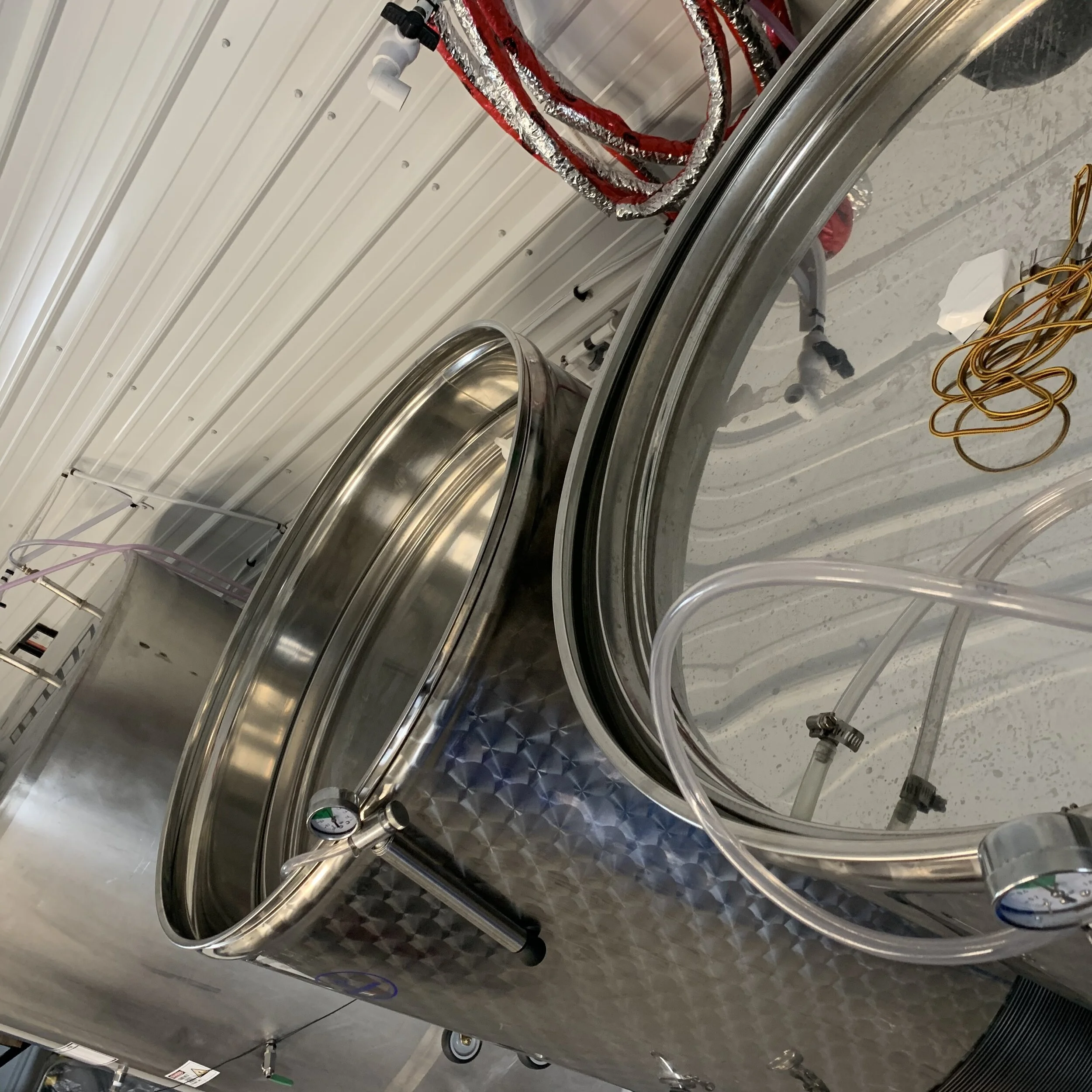

Daily Check of the Integrity of the Floating Lids and Cleanliness of the Tank

Daily Checks

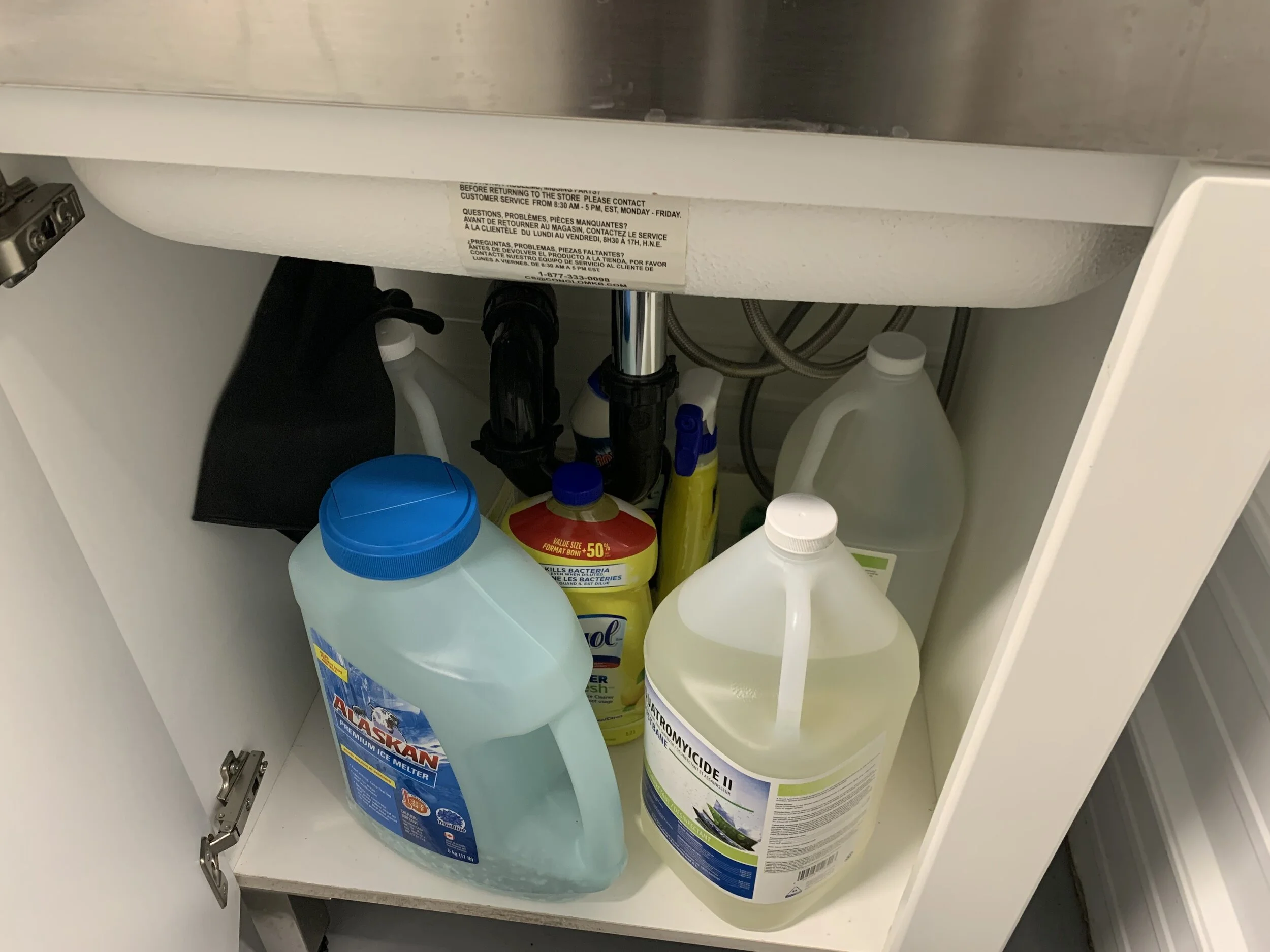

Sanitation checks: We have a comprehensive daily sanitation checklist. We do an assessment according to usage. If we just performed a specific event, we subsequently assess floor and mats, sink, wall and shelving for cleanliness and sanitation, and, of course, cleaning and sanitizing used equipment. This includes spot checks and, most often, a damp wipe with sanitizer (or more thorough clean if needed). Otherwise, we do a quick check of all floors, bathroom, lab areas, working surfaces, used ladders, stairs and whatever else is used or touched daily. Tanks are wiped down completely once weekly or as necessary for dust and fingerprints, with sample ports sanitized before and after every use. We also check outside for evidence of animal droppings (including wild animals) and seasonally for birds and insects (see pest check). We have to launder and return all cleaning cloths and mops as well.

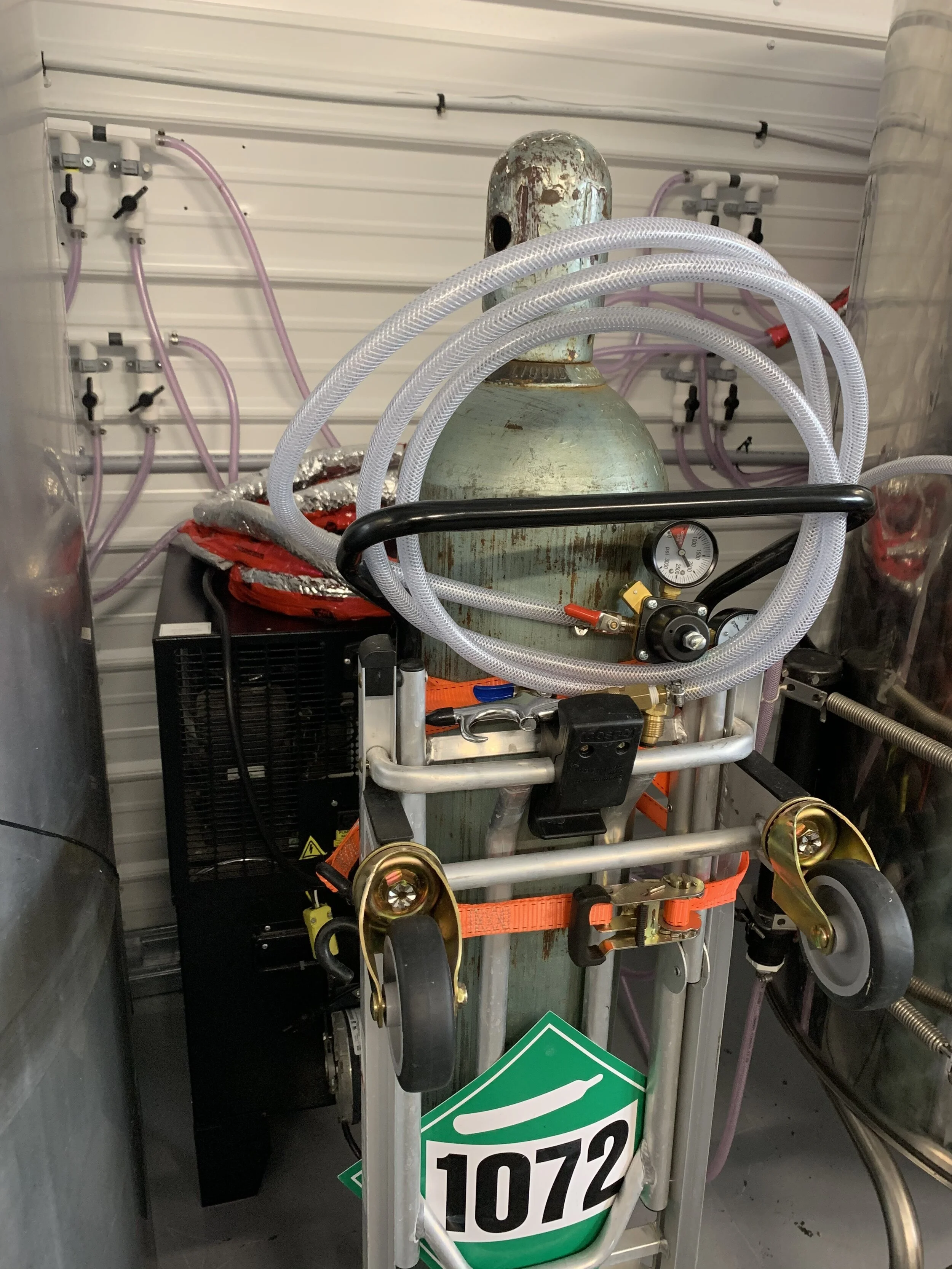

Active tank checks: One of the most important daily checks is to assess the integrity of the floating lids on the tanks, including the pressure gauges which control their rubber seals. We also assess the top of the tanks (using the platform ladder), making sure there are no leaks, no evidence of fruit flies or any debris or dust. Then we climb down and check the temperature gauges, sample ports, mandoor gaskets and pumping outlets for integrity. The floor is also observed for evidence of leaks from the tanks. The glycol chiller connections are examined as well. The chiller unit is assessed for operation if in use at that time.

Basic security checks: This activity includes a perimeter check, integrity of door closures and locks, integrity of windows, evidence of tampering or entrance. We check the operation of the security camera (remotely and on site). The key pad is assessed for correct operation.

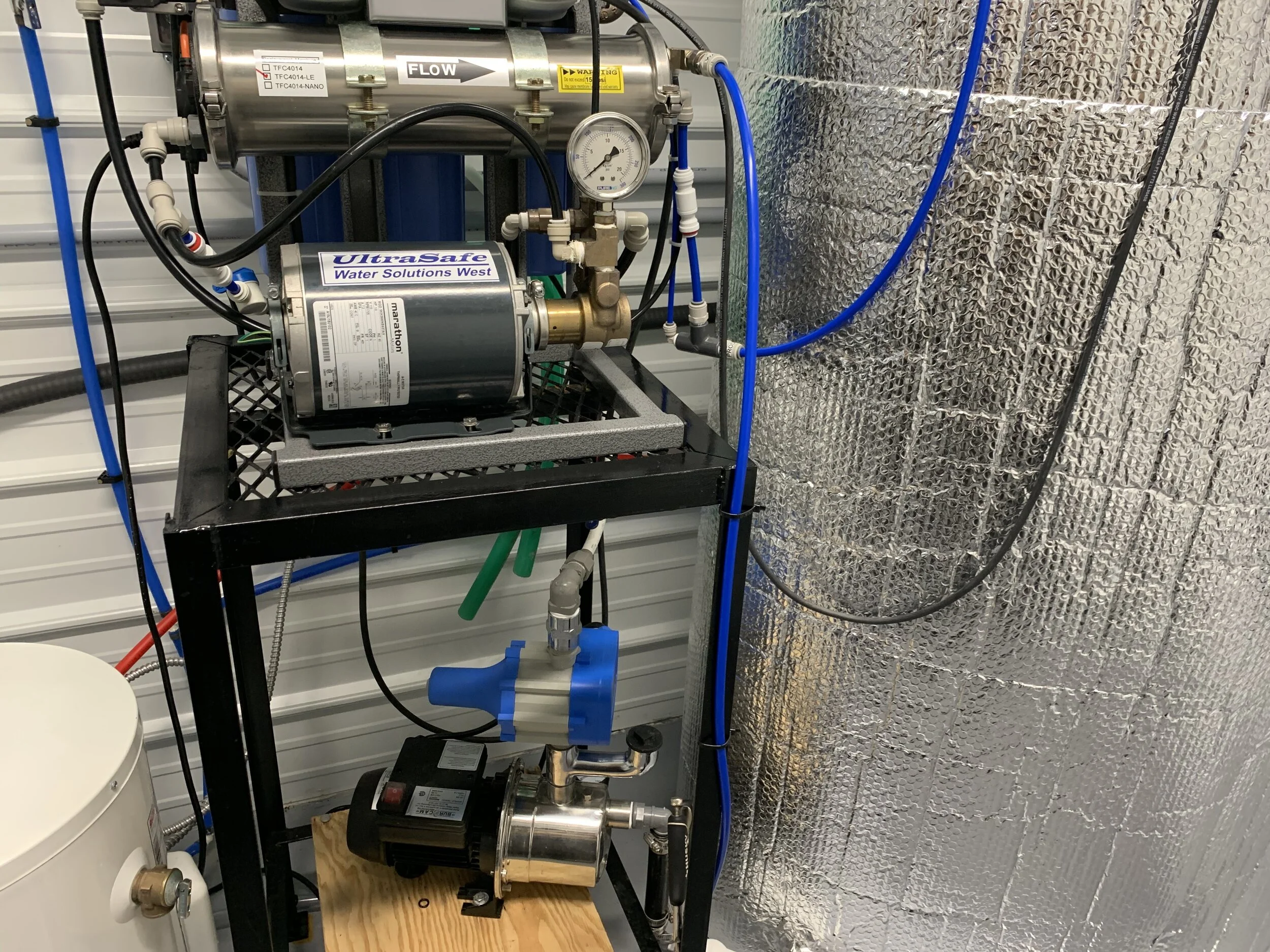

Other equipment checks: This activity includes R/O, furnace, heat pump, Venmar (if using at that time), ducting, fan, hot water tanks, hosing and faucets, bathroom fixtures, lab sink, plumbing under both sinks, all lab equipment shut off and secured, nitrogen tank intact and safely secured, and water flows.

Pest check: We have a specific seasonal checklist for pest control activities, some of which are performed daily even in winter (with particular attention to fruit flies and rodents).