Bee & ThistlE Winemaker Notes

Winemaker Introduction (March 12, 2019)

My name is Margaret MacInnis. I am the Winemaker at Bee & Thistle Winery. I completed the UC Davis (University of California) Winemaker Certificate Program in March, 2019 with honours. The studies began in September 2017. The modules included:

Introduction to Wine and Winemaking - completed December 2017

Wine Production - completed March 2018

Wine Stability and Sensory Analysis - completed June 2018

Viticulture for Winemakers - completed December 2018

Quality Control and Analysis in Winemaking - completed March 2019

The courses were intense; they were delivered online with weekly lectures in the ZOOM platform where we met with the instructor and classmates. Transferring all the knowledge from winemaking with grapes to fruit winemaking was a challenge I was prepared to face! In addition, several instructors helped during the adaptation phase. I am excited to venture into fruit winemaking with Haskap and Rhubarb and add other fruits as they become available.

Margaret, Winemaker, Bee & Thistle Winery Inc.

The Frozen Mist™ Project 2024

With the burgeoning popularity of RTD products (ready-to-drink) in Saskatchewan, Bee & Thistle Winery has several projects in the works for 2024 and 2025. The first of these is Frozen Mist™, a wine-based slushy-style beverage, with the addition of real Saskatchewan (or estate) juice and several proprietary ingredients. The part of making a successful slushy that freezes to the proper consistency involves the correct addition of sugar and various ‘gums’ for slight thickening and mouth feel, as well as the proper addition of acids to give the sweet yet tangy taste we all associate with slushies. The alcohol in the slushies comes from our own Haskap and Rhubarb wines, and the fruit juice is pressed or steamed on site. There are no artificial flavours or colours used.

All three of our Frozen Mist™ flavors passed their initial certificates of analysis (Q/A safety), as mandated by SLGA, our governing body. Approval of the process, the packaging and the format for retail sale was then sought. We are also permitted to introduce slushy machines to retailers and, by 2025, they will be using our machines to sell Frozen Mist™ over the counter in appropriately sealed containers (such as domed slushy cups with a security seal), much like the growler system currently in vogue for beer!

For 2024, we did a pilot project of 296 ml foil/PET stand up pouches which are proving to be very popular. Three flavours have been selected:

Frozen Mist™ Haskap

Frozen Mist™ Strawberry

Frozen Mist™ Cherry

We hope to add one additional flavour in 2025.

All of our Frozen Mist™ product line is lactose-free, gluten-free and nut-free. They do have quite a bit of added beet sugar (from Taber, Alberta) since that is a necessary ingredient to allow the slushy to freeze to the proper consistency, so if sugar is an issue for you, we suggest trying one of our dry wines (Haskap or Rhubarb DRY) instead. Of course, these products are NOT FOR CHILDREN since they contain 6.8% alc/vol. One 296 ml package serving (about 10 oz) is the equivalent of 1.13 standard drinks. They do contain acacia gum, which is generally non-allergenic, and a very small amount of sorbate and sulfites to allow for shelf stability.

Why do Yeast Make Ethanol? (March 13, 2019)

The short answer is because they can.

Don’t for a second think that yeast have brains and that they are producing alcohol for our benefit! The truth of the matter is, the ethanol is a by-product of a food system that allows yeast to grow, make energy and reproduce. Yeast belongs to the Fungus Kingdom. They are a single cell and generally reproduce by budding. During their life processes, they basically spit out ethanol and carbon dioxide as they process their “food”, which is sugar. The series of reactions are chemical ones.

Happy yeast produce ethanol from the sugars in our fruit, and you’ll be happy they did!

Ladybugs: Friend or Foe? (March 14, 2019)

The ladybug was first introduced to North America during 1916 from Asia (Japan and Korea). They are actively sold and marketed as a form of biocontrol against aphids and some small soft-bodied pests. One can purchase thousands of them for this purpose. While it has proven very efficient in certain pest control, MALB (multi-coloured Asian Lady Beetle) adults can accompany the fruit on the harvester and subsequently be transported on fruit to the winery; this is not an ideal situation. Unfortunately, if ladybugs are present during winemaking operations, they can produce off-aromas and flavours in the wine known as ladybug taint (LBT). Chemically, the taint is produced by an order of compounds defined as methoxy pyrazines, which isn’t of interest to most people, but Winemakers tend to be fussy about it!

Whilst Bee & Thistle Orchards encourages the proliferation of ladybugs to control aphids (particularly on Black Currants and garden vegetables), we conscientiously sort wine-destined fruit at the conveyor belt and washing stations; we don’t kill them but return them to the gardens as much as possible. We do not see more than one or two ladybugs per 100 pounds of fruit, and they are easy to spot and sort out. So, yes, ladybugs are both friend and foe. It depends on what you are growing or making. But we won’t be purchasing any for deliberate pest control anytime soon.

Haskap Acids

At the time of writing this post, I am studying the composition of the fruits I will be using to make wine.

Our signature fruit is Haskap.

Studies have been done to determine exactly what acids Haskap contains. Depending on the cultivar, the main acids of Haskap are Citric, Malic and some Quinic acid. Because most fruits (other than grapes) are so high in natural acids, higher than what would taste good in wine, Winemakers dilute the juice with water; natural Haskap has a sugar that would ferment to about 8 or 9 % alcohol but, remember, we must dilute that, so without the extra addition of sugar, our wine would not have the desired alcohol.

Screw Caps Versus Corks (April 2, 2019)

This post is to discuss the relative merits of screw caps versus corks. Exploring the relative merits and pitfalls of each is a very difficult discussion.

Primary is consumer acceptance and expectation, which also often includes a little misinformation and pre-conceived ideas on what corks can and can’t do, and what screw caps can offer.

Corks

Corks have a long-standing history, and generally will be well-received by most customers. In fact, consumers have been polled, and it has been found that most consumers believe better wine is always corked, not screw-capped. Why is this true? Well, corks are traditional. If you go to a discerning establishment, they often hand you the cork - and many people have no idea what they are supposed to do with it - look at it and judge it somehow ‘okay’….

In truth, the factor they are supposed to be looking for isn’t something they can visually test; to achieve some measure of validity, you must SNIFF the cork and see if you can detect some mousy, harsh moldy notes. You must also sniff and taste the wine for evidence of cork taint, which is the issue you are being called upon to judge.

What’s ironic is that not all people can even smell or detect low levels of cork taint, which is caused by levels of TCA in the wine (TCA is short for tricholoroanisole, a chemical produced by the reaction of wine with cork that has some mold factors in it). How many corks and bottles of wine will be affected? Some say as many as 5%; others argue one bottle in 100. At any rate, just because one bottle in a vintage has the cork taint does not mean they all will. But again, not all people detect the presence of TCA at low levels, and some can’t smell it at all!

What else do corks do? Well, the main thing they do is give the consumer an ‘experience’ that they like. Many people like the ritual of removing the capsule, taking out the cork, and pouring the wine.

Corks also allow a very small of oxygen in over time, which is said to age the wine gradually, through a series of chemical reactions. There are some modern-produced corks that are partially synthetic, and these will not have the TCA reactions. They are, however, quite expensive.

Test and Control Flasks - Addition (front flask) diluted in a scaled-down fashion as described below

Tasting cups are randomly labeled for blind sensory analysis

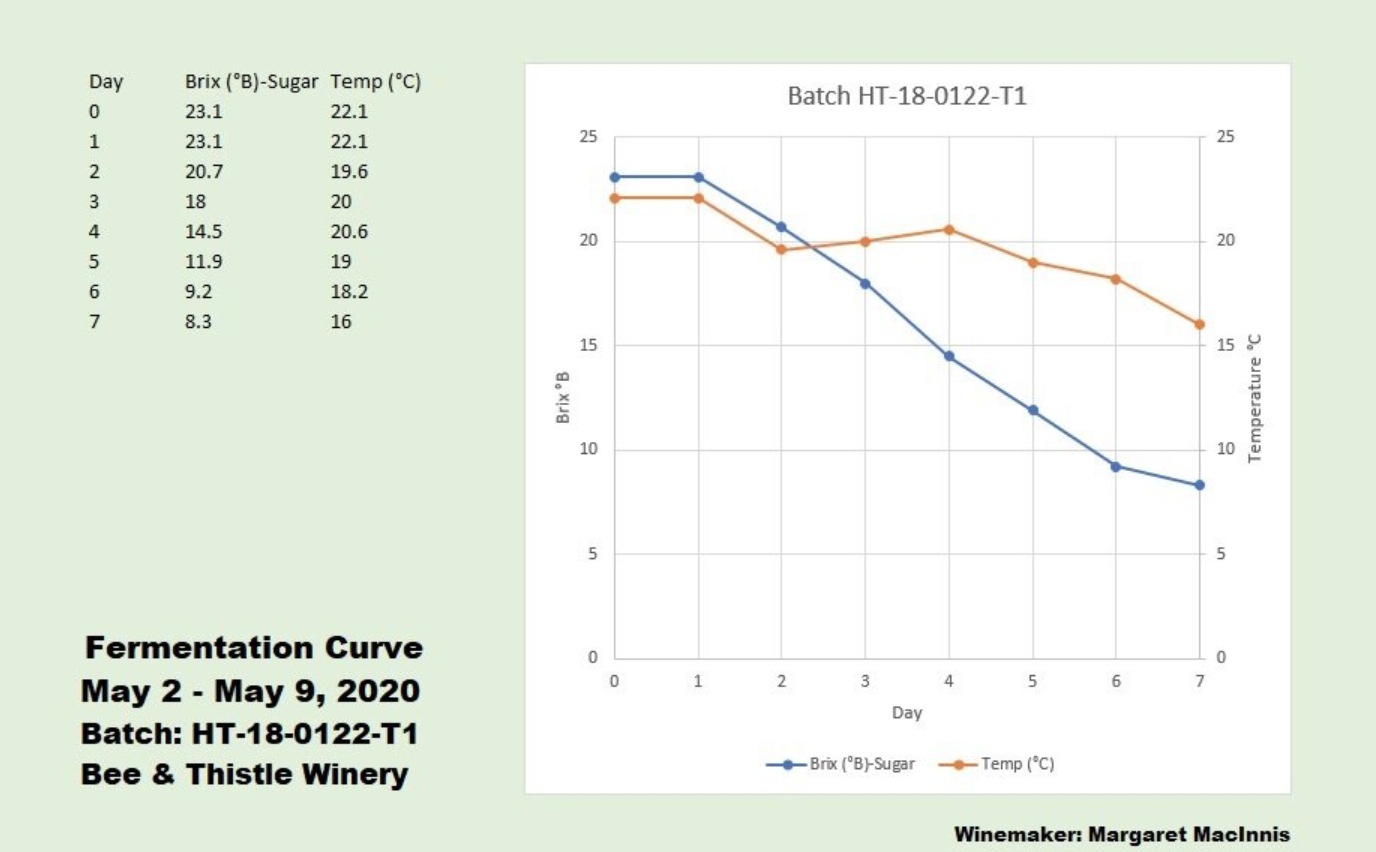

Brix - How Sweet It Is... (April 19, 2020)

Brix, or degrees Brix (°Bx), is defined as the number of grams of sugar in a measured weight of solution. 1°B or °Bx is 1 g of sugar in 100 g of solution or 10 g of sugar in 1000 g of solution (about one liter). Fruit inherently possesses some sugar, with only grapes having enough natural sugar and acid ratio to make wine directly without amending. Haskap fruit is too high in acid and too low in sugar to make wine without first diluting it with water and, secondly, adding sugar (the winemaking term for adding sugar is called chaptalization).

Yeast use sugar to make alcohol during their life processes. So, if you know how much sugar you have in your juice (or how much you added), you can approximate how much alcohol you can expect to be rewarded with at the end of fermentation. We measured Brix the first time before we pitched the yeast and found it to be 23 °Bx. This means that each 1000 g of solution had about 230 g of sugar.

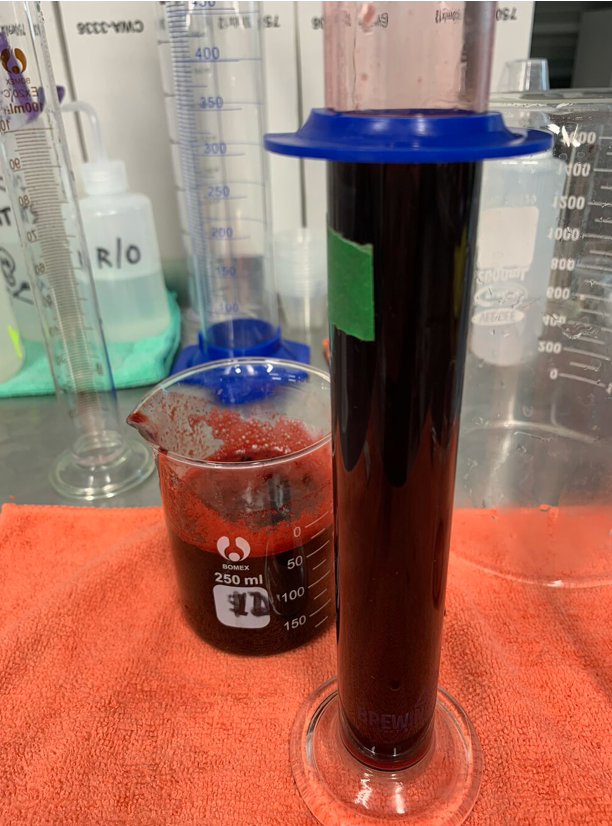

The measurement of specific gravity relative to water of the juice (specific gravity is the solids and such in your mixture) will be done with a hydrometer, and if the hydrometer is not marked in degrees Brix but a different scale, then you can use an equivalency chart to know what the number is. The hydrometer is photographed below in the measuring container which holds the fermenting strained juice/wine. It is measured in degrees Brix (°Bx).

The hydrometer is a very sensitive piece of equipment; well-balanced hydrometers that are certified by Science Directorate in Canada will set you back about $200 each (a requirement of Excise Canada) but, for daily use, a less expensive one will suffice. The ones we purchased were about $35 each and we are very careful with them. The SEDs are reserved for final alcohol calculations; they are not generally used daily.

The photo below shows a reading of 17.6 °Bx, read at the bottom of the meniscus (the meniscus is the lower part of the curved liquid made at the surface). From that, we calculate the progress of our fermentation, subtracting the reading from our initial reading (which was 23 °Bx). So we have used up 23 - 17.6 or 5.4 (°Bx), or 54 g of sugar in a liter of the fermenting wine. From that, we multiply by 0.55 or so, and approximate that our wine is now at about .55 x 5.4) or 3% alc/vol. We started with about 230 g of sugar in each liter of juice with the intent of making approximately 12.5% to 13.5% alcohol, written on the bottle as % alc/vol.

Many Winemakers use either Oechsle or Baumé scales instead, but the process is the same and just the numbers vary in how they calculate the same % alc/vol.

Reading of 17.6

°Bx - This is verbally stated as 17.6 degrees Brix

Sugar Choice

Because we were adamant from the beginning that all products used for actual fermentation be Canadian produced and acquired, we have chosen to use Taber Beet Sugar from Alberta, Canada. Since sugar beets are grown and processed in Alberta, Canada and sugar cane is imported, the choice was easy. The Taber Company identifies their Beet Sugar by starting their lot number with 22, notable in the photo below.

4.

The following photos show the orchards in full flower and then netted to prevent the birds from eating the Haskap berries.

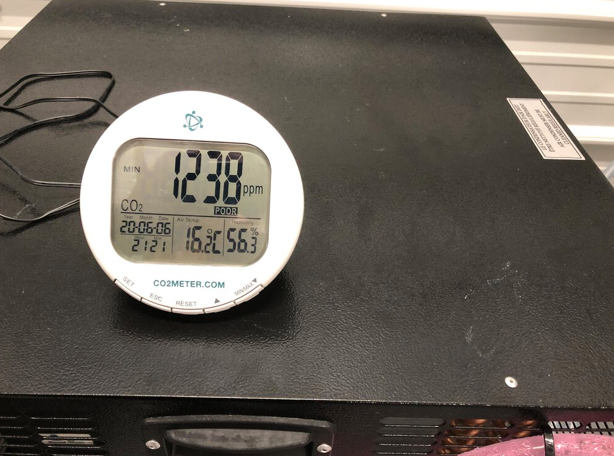

Carbon Dioxide: Dangers of CO2 in the Winery (June 8, 2020)

From the chemical formula:

C6H12O6 → 2 C2H5OH + 2 CO2

sugar yields alcohol plus carbon dioxide

It’s abundantly clear that the process of fermentation produces quantities of CO2, a colourless and odourless gas, which at specific parts per million in room air constitutes a danger to the health and safety of winery personnel. CO2 is twice as heavy as air; therefore, it will sink to the bottom of a room forming potentially deadly pools of gas that will displace oxygen (O2). CO2 has been found to settle in corners of rooms and in areas that are generally undisturbed with low ventilation. The presence of CO2 is not known until symptoms of exposure are experienced, or unless there is a CO2 meter. At peak fermentation the volume of CO2 produced in 24 hours may be 10 to 15 times greater than that which occurs naturally in air (normal room air has 350 ppm). Without adequate ventilation, CO2 can displace oxygen and produce an atmosphere that is both high in CO2 and low in oxygen. With a 1000 L tank in peak fermentation, it was clear to Bee & Thistle that the threshold for safety would be reached quickly.

It’s amazing how much CO2 is produced by the fermentation of sugar into alcohol. CO2 is measured by weight; in fact, it has been stated that when 1 pound (0.45 kg) of CO2 is produced, it creates 8.7 cubic feet (or 0.246 cubic meters) of CO2 . So then, that same amount of CO2 will raise the parts per million (ppm) of an average 1,000 cubic foot room by 1,000 ppm.

A few facts to understand:

Carbon dioxide (CO2 ) is a toxic gas at high concentration.

1,000 ppm: breathable and not dangerous.

5,000 ppm: over an 8-hour shift, this amount of CO2 would be the maximum allowed by OHS (Occupational Health and Safety).

10,000 ppm: breathing rate increases slightly.

30,000 ppm: breathing rate increases to twice the normal rate and a person will likely experience impaired hearing, headache and increased blood pressure.

50,000 ppm+: (STEL) short term exposure limit of greater than 5 minutes; Imminent Danger to Life and Health (IDLH). Breathing increases to approximately four times the normal rate, symptoms of intoxication become evident and slight choking may be felt.

60,000 ppm+: no exposure permitted as doing so could cause immediate loss of consciousness leading to death.

Bee & Thistle Winery has several safeguards in place to monitor and mitigate the hazards of CO2 exposure:

CO2 monitor between fermenting tanks, nearer the floor level as CO2 is heavier than room air

Venmar ventilation system, which draws air out of the room and replaces it with warmed outside air, maintaining the CO2 level below 2000 ppm.

An informational chart outlining the dangers and health effects of CO2.

Instructional material provided to all personnel as to what circumstances may result in high CO2 levels, how to monitor the CO2 situation, the limitations of mechanical ventilation, and what to do if the readings are high or unobtainable. There is a written policy to follow, which also includes use, care and maintenance of the Venmar and the CO2 monitor, and emergency measures and procedures to follow

Carbon Dioxide: Benefits of CO2 in the Winery (June 16, 2020)

Despite the bad reputation of CO2 and its effect on personnel safety, CO2 is also a friend in the winemaking process. Managed properly, a layer or blanket of CO2 on top of wine will prevent contact of wine with air. Wine exposed to air will cause many issues, including oxidation, increased activity of certain non-beneficial microorganisms and production of other undesirables (such as high volatile acidity—aka vinegar smell and taste, and chemical smells and tastes).

Pitching of Yeast: Official Start of Wine (June 19, 2020)

Every wine has an official start from a legal standpoint. Wine is not wine until the first drop of alcohol is made. Therefore, the official start of wine is the Pitching of Yeast.

Historically, Winemakers called yeast addition ‘pitching’. It is unclear exactly how this term started:

History and Etymology for pitch. Noun (1) Middle English pich, from Old English pic, from Latin pic-, pix; akin to Greek pissa pitch, Old Church Slavonic pĭcĭlŭ. Verb (2) Middle English pichen to thrust, drive, fix firmly, probably from Old English *piccan, from Vulgar Latin *piccare

How Do We Know When Berries Are Ready For Harvest? (July 13, 2020)

Winemakers who are responsible for deciding the harvest date of a vineyard rely on visual, taste, aroma, and chemical parameters to optimize the fruit for the style of wine they plan to make. Since we grow our own fruit for our wines, we have the pleasure of sampling and making such decisions in a more leisurely fashion.

Currently, our orchards are divided into 6 “blocks”.

Optimally, I would take a representative sample from each block every day or two; then examine, taste and chemically analyze. Treatment of all test samples is identical:

handpicked at random intervals throughout the block, including sun sides and shaded sides, top and bottom of random plants

washed gently in cool water, air dried, and frozen 24 hours in a Ziploc™ bag

crushed and treated with pectinase and glucosidases (aka enzymes) as per wine protocol (allowed to macerate for 6 hours)

pressed for juice

Brix, pH, and TA (titratable acidity) are measured, and colour and aroma assessed

ratio of 35-40 percent juice and 60-65 percent water with Brix adequate to obtain a final Brix of 20.5 to 22.0

assessed again for colour, pH, TA, taste, and aroma

Block 1: Home Acre Indigo Gem and Berry Blue: with a 4:1 ratio 7 rows 45-65 plants each 7 years old

Sample 1: July 8, 2020

Weight 360 g: Brix was 12.5, pH 3.0, pH and TA more acidic still; the decision was made to wait 3 more days and test again as the Brix was not ideal, and the product still a little acidic and tart for wine, although these kinds of berries make excellent jam and toppings! One procedure we follow when testing berries for ripeness is cutting them open and looking for solid red/indigo colour throughout plus assessment of the seed maturity. In this sample you can see that the berries aren’t optimally ripe; if they were, they would not have any red spots and the colour would be indigo blue throughout.

Sample 2: July 11, 2020:

Weight 360 g: Brix was 13, pH 3.1, less acidic. Again, we need to wait a little longer. Berries tasting sweeter and looking ripe.

Sample 3: July 13, 2020

Weight 360 g (left sample), the right is another sample from Block 3a. You can already see that the colour is deeper and more uniformly indigo blue. This sample has a Brix of 14 and is indicative of being nearly ready for harvest. The taste is optimal, and the colour of the cut berry is also uniformly ripe. The seeds are starting to look ripe as well. We will be starting Block 1’s harvest on July 15.

Block 2: Home Acre Tundra and Berry Blue: with a 4:1 ratio 6 rows of 65 plants each 7 years old

Sample 1: July 13, 2020

The Brix of each sample is checked, along with other parameters to determine suitable harvest time. During the lab assessment, the dilution ratio of each sample to provide optimal product to ferment is established. For example, this sample was diluted 35%: Brix 14.2 juice, with 65% Brix 26 water (sugar added) and the pH, TA, and taste/aroma were determined to be optimal.

For example, if I want a final Brix of 21, I will make my water at Brix

(35 x 14.2) + (65 x X) divided by 100 = 21

X = Brix of 26

Sample 2: July 15, 2020

Block 3a: North Orchard Indigo Gem and Berry Blue, some Smart Berry Blue and some Aurora: 12 rows, 8 with 205-10 plants each and 4 with 120-170 plants each, the South 50 plants of Rows 13 to 20 are also included since they are prone to both drought and flooding and are more stressed than Block 3b. Most are 5 years old, some younger at the roadside (4 years old); some mole damage and susceptible to flooding or drought and wind. Seems to ripen more quickly. Considerable weed pressure in this block too. General stress.

Sample 1: July 13, 2020

Sample 2: July 15, 2020

The second sample indicated this block was ready for harvest on the 15th, with a Brix of nearly 15.

Block 3b: North Orchard Indigo Gem and Berry Blue, some Smart Berry Blue and some Aurora: 4 rows mature 6 and 7 years old, 210 plants each. North 155 plants of Rows 13 to 20. Healthier and protected from the wind. Seems to ripen less quickly than 3a, but more quickly than Block 4 (which is primarily Tundra and later anyway). Less weed pressure and healthier plants than Block 3a. Some boron deficiency noted.

Sample 1: July 13, 2020

Sample 2: July 15, 2020

The second sample indicated this block was ready for harvest on the 15th, with a Brix of nearly 15.

Block 4a: North Orchard Tundra and Berry Blue, some Smart Berry Blue and some Aurora. Healthy, protected and stress-free plants. First 12 rows, and North half of last 10 rows. Mostly mature 6- and 7-year-olds. Some evidence of boron deficiency. Little stress otherwise.

Sample 1: July 14, 2020

Sample 2: July 16, 2020

The second samples were more than ready to harvest, at a Brix of nearly 15, and definitely great colour throughout the berry.

Block 4b: North Orchard Tundra and Smart Berry Blue, more Aurora here. This area is the top of the hillside South of Rows 13-22, which had drought stress in the first 3 years, although is currently thriving. Plants are mostly 5 or 6 years old and now healthy, with the area of the hill having better drainage in this rainy season of 2020. Some evidence of boron deficiency.

Sample 1: July 15, 2020

Sample 2: July 17, 2020

Again, samples were done as indicated. We then got busy with harvest and, with the final samples, decided the order of harvest.

It was a good exercise, and with the sample notes in hand, it was easy to decide which blocks to harvest first. We also label buckets with block numbers and areas so that we can plan for additions and correct wine making decisions which will optimize the flavour, aroma and profile of each batch according to the berries we harvested.

Chiad Fhion Haskap Wine - 2019, 2020, 2021, 2022 (post created August 21, 2020)

Following several months of test batches and practicing our routines, we were finally prepared to initiate full-scale fermentation. Exciting times!

Vintage 2020

Our Haskap wine journey was started with 2020’s frozen July harvest. Vintage 2019 was started a month later from stored fruit.

Growing Season Report: 2020 was a bit of a challenging year for Bee & Thistle Orchards, with a delayed spring and late bud break in addition to temperatures being suboptimal. Flower drop following pollination was in early June, with veraison (turning blue) of the berries occurred on June 25. Using that date, we predicted harvest readiness on July 15, assuming adequate rainfall and sunshine. With an excess of rain and suboptimal sun hours, the berries were a little high in malic acid, but average Brix was close to a respectable 15. Colour in the berries was very good, with a deep crimson indigo throughout the fruit. Therefore, harvesting commenced as predicted in mid-July.

Fruit Available Report: We harvested nearly 12,000 pounds of Haskap in 2020. See our post on how we knew when the berries were ready for harvest, as well as a video of our 2020 harvest: the fruit will be fermented in small batches of 1000 L per batch until all is gone!

August 21, 2020

A large quantity of haskap in pails were brought from the freezers and thawed, then crushed into the large primary fermenters.

August 30, 2020

Haskap Wine Vintage 2020, 2,000L was progressing very well with temperature-controlled fermentation to accent the fruity aromas and flavours inherent in Haskap. It took about 2 more weeks to finish fermenting and then the work of stabilizing, finishing, subtle adjustments, and aging began.

Next batches, January and February 2022

From January 15 to February 15, 2022, 3000 L of Haskap Wine Vintage 2020 will be fermented and processed as planned above. The flavour and profile of this fruit harvest (from frozen fruit) is expected to be as award-winning as our initial batch, which garnered 92 points at the New York International Wine Competition in 2021.

Bottled: End December 2020 and Mid January, 2021

Released Date: End January 2021

Sold Out first batch: April 2021

More available from subsequent batches: October 2021

June 2021

Batch 2, 2020: Started June 2021 1000 L, will be made into fortified dessert wine (The Abbey), Haskap MIST™, and regular Semi-Sweet and also Dry table wine; progressed much the same as batch 1 (2020) and finished fermentation in a timely manner. A new batch will be started and dedicated to strictly fortified dessert wine and bottled in 375 mL flint Bordeaux bottles with Tcaps and security seals, branded as The Abbey.

October 2021

Bottled Haskap DRY 20 cases.

Vintage 2019 (Aged)

Our next Haskap wine ferment was started with 2019’s frozen harvest.

Growing Season Report: 2019 was a bit of a challenging year for Bee & Thistle Orchards, with a delayed spring and late bud break in addition to colder than normal temperatures right up to harvest week. Traveling plans and logistics had our harvesting a little sooner than optimal, therefore, the fruit will be handled with an eye to reducing the less than ripe character. We also had an excess of rain, and the fruit was a bit less concentrated, with an overall Brix of just around 14. Colour in the berries was very good, although we did determine we would need to macerate and ferment on these berries a bit longer to release the tannins and aromas and to maximize colour extraction.

Fruit Available Report: The winery has purchased 3 pallets of fruit from the Bee & Thistle Orchards. One pallet was used for this batch and the other two will be used in late December after the Rhubarb wine tanks are free.

September 25-26, 2020

Pails of Haskap were brought from the freezers, thawed in pails, crushed into the large primary fermenters, sugar and water added, with amendments and adjustments done as well.

January 2021

Very successful attributes are noted whilst this wine continues to age beautifully. Oak chips and final filtering and finings with appropriate products are in progress.

²sur lie: French ‘on the lees’: aging wine on lees; this practice keeps the wine in contact with the dead yeast cells, adding flavours, aromas, depth, and complexity. If fruit is immature or has evidence of Botrytis, this practice would not be advised as it would concentrate the negative attributes instead of accenting the positive ones.

Tank aging to May 2021: Tank aging to develop flavours and give the customer a chance to taste the more aged Haskap wine.

Bottled May 2021: 70 cases.

Released for sale: May 2021

Sold out: July 2021; more made in a new batch below, available August 2021

New batch: late January 2021

CF5 2019 Vintage: 2000 L started with a new yeast and has progressed. This yeast is noted for high aroma producing capacity, and easily captures the essence of Haskap at a lower fermentation temperature. Wine was fermented ‘on fruit’ until Brix 8 or sp.gr. approximately 1.030 to ensure maximum fruit flavour extraction. Again, we chose the yeast derivative enhancer dedicated to more immature fruit. This time we dared to start at a higher alcohol potential Brix, which should give us a finished alcohol of closer to 12-13.5%. This would be the ideal starting point for our new product, Haskap MIST™, requiring less wine and allowing for the addition of more juice! Our Haskap MIST™ product has a proprietary secret ingredient list, which definitely includes a good amount of real Haskap juice and provides a real punch of flavour.

Mid February 2021

The fermentation of this lovely batch of wine is completed. Finishing tasks were performed (including racking and rough filtering), while we opened our winery for sales! This will probably be the busiest season in the lifetime of our winery.

End February 2021

Because we were very busy with the first month of winery opening and sales, the decision was made to allow this batch to tank age a bit longer, which will allow us the opportunity to finalize our plans for it. Since it is pleasing when quite dry, we are going to experiment with several options and will possibly divide this batch to best determine our course of action. And a little tank aging never hurt a wine. Of course, the parameters will be closely monitored, and adjustments made as necessary.

Early March 2021

We’ve added another 1000 L batch of the 2019 berries to the primary tubs, and will blend these two CF5s together once they are both finished, to allow them to age blended in the 2100 L tank. They are being treated in precisely the same way. Then we can opt to use some for Haskap MIST™ as required and finalize our plans.

Mid March 2021

We’ve filtered and done preliminary adjustments to the first batch, including addition of some select products to enhance the fruit-forward attributes. This batch is testing at relatively high alcohol (13%) and will be blended with the lower alc/vol (12%) second batch. Balance in fruit wine is achieved by balance in alcohol as well as many other things, and this level of alcohol is just a little higher than optimal for a balanced taste test on 7-week-old wine; we’ll blend and adjust until we get the level we want. In saying that, the other attributes, including flavour, colour, aromatics, and finish, are very good to excellent. This gives me confidence this is a very nice batch and will only improve upon further aging and slight adjustments to accent the natural flavours and aromas of Haskap, and to bring out its potential in wine.

Mid April 2021

Blended CF5i and CF5ii: 12.5% alc/vol

To June 2021: Tank aging and final adjustments/finings

Bottled: 225 cases, early July 2021

Released to Market: August 2021, delivered a quantity to Alberta as well.

New batch: June 2021

CF7 2020 + 2019 Vintage: 1000 L started with a new yeast and has progressed. This batch should work out well for proposed Haskap Dry and possibly some more Haskap MIST™ and a new product, Haskap Fortified at 19.5% alc/vol Eau-de-Vie.

July 2021

The fermentation of this lovely batch of wine is completed and the aromas and tastes are awesome!

End August 2021

Aging time—the parameters will be closely monitored, and adjustments made as necessary.

The other attributes, including flavour, colour, aromatics, and finish, are excellent. This is a very nice batch and will only improve upon further aging and slight adjustments to accent the natural flavours and aromas of Haskap, and to bring out its potential in wine. Alc/Vol before back sweetening has a good balance and with appropriate tannins and a little oak, this will be a great new product for Haskap DRY.

Plans to Bottle:

Haskap DRY (with little sugar added 10 g/L so sweetness level 1), bottled 20 cases October 2021, released November 2021

CHIAD FHION Haskap Regular our brand award-winning wine with our normal sweetening protocol

THE ABBEY Haskap Fortified Dessert Fruit Wine, preliminary testing SLGA approved 19.5% November 2021

New batch: mid July 2021

CF8 2021 Vintage: 2200 L started directly from harvest in mid July, with amazingly ripe fruit and a very advanced flavour profile. The summer was extremely hot and a little bit of water restriction due to lack of rain does develop very flavourful fruit with a good amount of natural sugar! We did lose a quantity of this harvest due to a premature hailstorm on June 7, just as fruit was beginning to set.

Mid August 2021

Fermentation completed.

Aging time will begin soon - the parameters will be closely monitored, and adjustments made as necessary.

The other attributes, including flavour, colour, aromatics, and finish, are excellent. This is a unique batch and will only improve upon further aging and slight adjustments to accent the natural flavours and aromas of Haskap, and to bring out its potential in wine.

Sept-December 2021

Tank aging at 12C. This is being sampled weekly and continues to develop beautifully with a unique flavour profile likely dependent on the hot dry year we had.

Chiad Fhion Haskap Fruit Wine CF8

Haskap MIST™ batches MT 5 and MT6

2 batches of The Abbey Fortified Haskap Dessert Wine HF1 and HF2

600 L distilled for the fortified, both The Abbey and Kinlochaline.

Jan-March, 2022

2200 L of CF9 were fermented and left to age in tank through to June 2022, using some of the remainder of 2020s fruit from frozen storage. This batch will also be multi-purposed as was CF8, into Haskap DRY, regular Chiad Fhion Haskap, Fortified The Abbey and Kinlochaline, as well as Haskap MIST™.

Additional batches were made throughout late 2022 and into 2023 and 2024.

Several new products are being trialed as well. One exciting release planned for late Spring, 2024!!

Rhubarb - 2019 to 2021 (October 20, 2020)

Rhubarb Wine Vintage 2019

From frozen German Wine Rhubarb, Rhubarb wine vintage 2019 was started in late May 2020. We began with approximately 800 L.

From the results of those trials, we fined with selected products, settled, and filtered through the stages, and back sweetened according to taste and desired profile.

THE COLOUR STARTS OUT VIVID BUT AS WINE DEVELOPS, IT SUBDUES

Rhubarb Wine Vintage 2020

We harvested the German Wine Rhubarb in mid-June 2020 and froze the fruit for two weeks. Frozen fruit is easier to macerate, and it releases its juice more readily than fresh. We began with approximately 800 L of Rhubarb wine vintage 2020.

The wine was allowed to settle and mature a bit before being blended with a small quantity of Haskap, which was trialed in the lab and found to accent the attributes of the German Wine Rhubarb, as well as providing a bit of mystique to the final profile.

The resulting blend was melded and aged for a further time, during which time we also fined and filtered similarly to LA2019, and back sweetened to a slightly lesser degree. Since the profile was a bit more intriguing, we did not want to mask the astringency and development of the tannin, which had complexed nicely over the course of tank aging and will further develop in bottle. We also balanced the acidity profile. The colour is just a hint stronger than LA2019, which we expected. Very nicely balanced wine, a bit tart and a bit sweet (but not too much), with classic Rhubarb palate and nose, and tropical overtones.

Rhubarb Wine Vintage 2021

June 2021

Loch Aline Rhubarb with Haskap 2021 started off from a very hot dry harvest condition, but despite the challenges of the year (including hail on June 7), the fruit has higher than average Brix and a very favourable flavour profile. Enough was collected to prepare a 1000 L batch, with the usual expected fermentation time allowed. The nutrients, yeast, and stylistic choices for this wine are similar to those used for 2020’s wine, which had a very promising and award-winning taste profile, garnering 90 pts at NYIWC (Bronze Medal), so it was decided to adhere to that plan. With a few tweaks to possibly create an even better batch.

Fermentation completed and aging began. Very lovely colour, a bit pinker than either 2019 or 2020’s batches (probably due to the heat and early ripening), with a slightly more varietal rhubarb profile too! Promising.

September and October 2021

Aged in a tank. This is definitely a lovely wine, with true varietal flavour and very clean crisp. It will make a lovely Rhubarb DRY, with just a slightest hint of sugar at 10 g/L. A further portion will be sweetened more so, and be similar to 2020's award-winning vintage.

October 24, 2021

Bottled 50 Cases Loch Aline 2021

Bottled 40 Cases Rhubarb DRY

January 2022

Remainder of 2021’s German Wine Rhubarb started fermenting, with an expectation of bottling in May/June. Same flavour profile, yeast, and conditions as the previous batch done in June, 2021.

April 2022

Bottled very nice batch with high colour. Split between Rhubarb Dry and Loch Aline Rhubarb 2021 Batch LA4.

July 2022 into 2024

Several more batches are planned or underway now that our basic processes are finalized and modified.

A Day in the Winery (October 30, 2020)

Specific Events

Putting on a batch: This involves acquiring fruit (a 5 hour round trip to Saskatoon freezers), thawing and crushing fruit, adding amendments according to tests and allowing maceration to occur. At this time, we also do tests to determine the timing of pressing and what yeasts and additions will be used. And, of course, ongoing washing and sanitizing of all equipment used and surfaces touched.

Monitoring an active ferment: If there is an active ferment underway, the Winemaker or assistant may be punching down, stirring, testing for Brix and acidity, assessing aromas and flavours, deciding to rack or filter, blend, or prepare for bottling.

Racking/pumping from tank to tank: This process occurs after ferment is complete, following rough filtering and/or fining, or any time lees are deemed to be excessive. It will also be done during bottling.

Monthly sanitation regimen: This is done according to a predetermined list close to the 20th of the month and takes about 4-6 hours for one person; two people can complete it in about 3 hours. It takes longer in summer due to dust prevalence.

Daily check of the integrity of the floating lid and cleanliness of the tank

Daily Checks

Sanitation checks: We have a comprehensive daily sanitation checklist. We do an assessment according to usage. If we just performed a specific event, we subsequently assess floor and mats, sink, wall and shelving for cleanliness and sanitation, and, of course, cleaning and sanitizing used equipment. This includes spot checks and, most often, a damp wipe with sanitizer (or more thorough clean if needed). Otherwise, we do a quick check of all floors, bathroom, lab areas, working surfaces, used ladders, stairs and whatever else is used or touched daily. Tanks are wiped down completely once weekly or as necessary for dust and fingerprints, with sample ports sanitized before and after every use. We also check outside for evidence of animal droppings (including wild animals) and seasonally for birds and insects. We have to launder and return all cleaning cloths and mops as well.

Active tank checks: One of the most important daily checks is to assess the integrity of the floating lids on the tanks, including the pressure gauges which control their rubber seals. We also assess the top of the tanks (using the platform ladder), making sure there are no leaks, no evidence of fruit flies or any debris or dust. Then we climb down and check the temperature gauges, sample ports, man door gaskets and pumping outlets for integrity. The floor is also observed for evidence of leaks from the tanks. The glycol chiller connections are examined as well. The chiller unit is assessed for operation if in use at that time.

Basic security checks: This activity includes a perimeter check, integrity of door closures and locks, integrity of windows, evidence of tampering or entrance. We check the operation of the security camera (remotely and on site). The keypad is assessed for correct operation.

Other equipment checks: This activity includes R/O, furnace, heat pump, Venmar (if using at that time), ducting, fan, hot water tanks, hosing and faucets, bathroom fixtures, lab sink, plumbing under both sinks, all lab equipment shut off and secured, nitrogen tank intact and safely secured, and water flows.

Pest check: We have a specific seasonal checklist for pest control activities, some of which are performed daily even in winter (with particular attention to fruit flies and rodents).

Update December 2020: We have fined and filtered the Haskap wine (Chiad Fhion 2020) as indicated above, and the results are as predicted by bench trials. This portion of the batch was bottled on December 22, 2020 and the colour is intense and true. The remainder of the batch will be treated in the same manner after 2 more weeks in the tank (due to work commitments outside the winery).

Black Currant Limited Reserve Small Batch Angus Ban (January 25, 2021)

It started as an experiment and ended up as a surprise. Sometimes good things really do come in small packages. Just 20 L, 26 bottles of nectar.

August 2020

Handpicked on a hot summer day from Ravensfield Farm from two-year-old Currant bushes; the berries were lush and decadent. We sampled a few. A cold wet spring followed by a wet summer turned into a balmy and hot few weeks which finalized the ripening of these perfect Ben Nevis Black Currants, and the stage was set.

September 2020

On a crisp fall day in September, we released the sugar of the berries to meet up with yeast; the sequence of events that ensued wasn’t particularly controlled, yet it progressed perfectly with very little help. Sometimes, the best wine is the one least interfered with.

December 2020

In late December, the fermentation had turned a few hand sorted precious pounds of Black Currants into a flavourful wine that had settled beautifully, with rich, deep ruby tones and a striking profile inherent to these berries: slightly woody yet sweet, slightly tart yet smooth and delicious. Dessert-like and powerful, evocative of the very terroir the fruit experienced in its short life.

December 26, 2020

Carefully bottled 26 bottles. Each bottle was signed and numbered by the Winemaker.

Summer, 2021

Additional small batches are being fermented from this year’s fruit. Each batch will be numbered 1 - 26 and sold individually.

Haskap MIST™: Tempt Your Tastebuds - Light 8% Flavoured Wine Beverage With Ripe Berry Juice (Feb 1, 2021)

We have developed a light 8% alc/vol, yet flavourful fruit wine beverage. Pluses? Flavoured with real Haskap juice, the effect is one of a nice crisp sweeter light in alcohol beverage, with the bonus of real juice. Haskap has the flavour of cranberry, raspberry, black currant, and cherry all in one glass. Some say it has a very pronounced blueberry note too.

Haskap MIST™ is a real crowd pleaser; you can enjoy a lighter glass of wine without feeling the effects too quickly. This is the perfect drink for summertime in a convivial atmosphere.

And best of all? This is as light on the palate as a fresh early summer day, without being overpowering. Tangy and sweet. Packed full of flavour. No harsh chemical tastes. Tempt your tastebuds with the flavour of summer berries in a glass.

Black Currant "MacAngus" 2020 New Small-Batch Select (May 8, 2021)

We decided to purchase a pallet of beautiful ‘Whistler’ Black Currants from our good friends in Ontario. Popham Lane Farm grows quantities of luscious flavourful currants. They were also kind enough to send us several samples of their preserves and jams. Decadent! The care and attention they give to their crop is evident in the flavour and quality of their products. I hope we can do their fruit justice by crafting a fine table wine, as flavourful as the berries we received! We are hoping to get sufficient product from Collin’s Ravensfield Farm this year to create another exclusive batch of Black Currant Reserve in the fall.

They have miles to go before they ferment. Joseph Hayes, owner of Popham Lane Farm, carefully loads his cargo onto a transport truck.

May, 2021: Black Currant “MacAngus” fermentation underway. Small-batch processing assures attention to detail and maximum flavour and quality wine for you to enjoy.

May 12, 2021

Fermenting is going very well. In fact, we’ve had to cool the batch down considerably! Today, we pressed out the fruit and returned the fermenting juice to a dedicated glycol-chilled 1000 L tank. The pomace will be composted and used as fertilizer for our orchards.

May 21, 2021

Fermenting is about finished.

June 2021

Fermentation completed and the work of finishing has begun—-racking, filtering, minor adjustments, aging a bit, then fining, aging some more. We expect this wine to be in tank for another 3-4 months before we achieve the taste profile we are looking for—and then we’ll bottle this goodness for you to enjoy in the Fall of 2021. The taste profile is complex but young, with the expected somewhat ‘woody’ flavours characteristic of Black Currants expected to mellow in the coming months.

July 2021

Aging continues. Really nice profile expected to develop well.

August 2021

A bit of work was done to back sweeten, adjust the taste profile, and with the addition of a little süssreserve (natural sweet black currant juice which is returned to the already fermented wine to sweeten and flavour it), it is coming along very nicely. It needs at least another month to meld flavours and develop the tannin structure to balance the alcohol, which is still a little heady and predominant.

September 2021

After another month of aging and a few adjustments, and lots of tastings, plus a little fining, this wine is ready to bottle. The last 3 weeks before sales commence will both serve to mitigate bottle shock, and further balance the flavours and alcohol with the aromatic profile. Very pleasing wine!

October 2021

Bottled 90 cases. Released to market.

February 2022

The remainder of the Popham Farm Black Currants was fermented and set aside for aging in tank until May, then they will be amended and fortified to create Kinlochaline Fortified Black Currant Dessert Wine in June 2022. Will use 200 L for the fortified, and 100 L for regular MacAngus bottling.

Mid January 2022

A small quantity of Popham Lane Black Currants is now undergoing a modified version of carbonic maceration popularized by the Beaujolais region of France, in their Beaujolais Nouveau Gamay wines. This is an experiment, and we are hoping to derive some unique flavour profile by this method. Essentially, carbonic maceration involves allowing the uncrushed fruit to macerate and ferment internally, under a blanket of carbon dioxide. After the juices are released and the fruit flesh is exposed, the fermentation starts as normal, with the addition of yeast and nutrients. You can read about Beaujolais Nouveau in France to get a feel for how this method may be used in a modified way to help expand our wine profiles.

Late January 2022

Fruit was crushed and water, sugar, yeast, and nutrients were added as normal. Then allowed to ferment for several days, and fruit was pressed. Pomace discarded to the compost pile in the home acre orchard for orchard amendments.

Modified carbonic maceration: A unique technique to develop fruity wine from Black Currants

Introducing Caisteal Rosé (October 6, 2021)

With the blend of German Wine Rhubarb, Strawberries, Haskap, a little Crabapple, and Raspberries, a fine new product with a blush of colour and a gentle taste profile, much care and attention was given to create a gentle wine with a smooth flavour and visual appeal.

Watch for the release of this special occasion wine with our Christmas Promotions.

Bottled November 21, 2021: 14 cases of 750 ml bottles and a few cases of 375 ml bottles for Christmas promotions.

Bottled December 20, 2021: 28.5 cases of 750 ml bottles bottled for release in January 2022

Further batches are being made as demand increases for this fine product through 2024.

ANGUS BAN Limited Reserve Small Batches Exclusive (October 12, 2021)

We carefully harvested Ravensfield’s Black Currants, and hand-selected and froze the fruit which was exclusively small batched into individual 23 L batches. There are 5 individual carboys, and they will be treated with special care and attention.

Fermentation began in mid-August.

September

First racking in mid-September and fermentation completed.

October and November

Aging and finishing through October.

December 2021

Continued aging and finishing. These will be bottled in early 2022. Intense, earthy, bold, full-bodied. What a Black Currant Wine should be!

January 2022

Bottled the end of January 2022

15 select cases set aside for premium aging and development for 4 - 6 months.

May 2022

Released this wine for sale.

Winemaker’s Notes

The flavours and aromas of Ravensfield’s Ben Nevis Black Currants surpass any currants we have tasted or experimented with. They are big, bold, with delicate woody characteristic earthy flavour and pleasing aromas, developing into a one-of-a-kind wine. Perhaps the Saskatchewan climate and terroir contributes to the unique profile of these amazing currants. In 2022, we hope that the weather and harvest cooperate to produce a full 1000 L batch of this nectar.

August 2022

Harvested and hand sorted this year’s production of prime fruit at the peak of quality and ripeness. Immediately transported to the winery and crushed into a new premium estate batch of Angus Ban, with the expectation of bottling and finalizing in early 2023. This will include a batch of Kinlochaline as well as a bottling of Angus Ban regular wine. Showing superior flavour and aroma profile in the fruit due to the optimal growing conditions in 2022.

The Abbey Black Currant Fortified Dessert 19.5% (December 3, 2021)

A little primer on fortified wine in Canada

In the basic sense, fortified wine is fermented wine that includes the addition of distilled alcohol to raise the alc/vol to above 16% (usually from 17 to 22.5 %). This is done in several ways depending on the stylistic goals of the Winemaker and the limitations of the rules we follow. The two main methods involve fermentation, either completely or partially, and fortification at different stages of the fermentation (to either stall or amend the fermentation). If you wish to read about fortified wine around the world to get a sense of what we are making, refer to Robert Bell’s Fortified Wines of Canada for a full explanation.

November 2021

Different types of spirits are generally used for fortification. What makes Bee & Thistle’s Fortified Haskap Dessert Fruit Wine so special is the addition of true Haskap distillate, or eau-de-vie, which is distilled from the wine that was fermented from our premium Haskap varieties. The true name for the distillate made from fruit wine is fruit brandy or eau-de-vie and, in our case, Haskap eau-de-vie. The wine used for this ambrosia was from 2021’s highly flavourful and intense berries. Due to the extremely hot and dry summer we had, the flavours of the berries intensified and that is further accented in the wine. With the supervision of Mark Holinaty of Great Gido’s Homebrew, Peter distilled a quantity of our premium fermented Haskap wine and used that distillate to fortify the same vintage batch it came from (2021). The flavours will be allowed to blend and intensify over the coming weeks. A small batch will also be aged; eventually, we hope to age a batch in oak for a year, creating even more intensity and flavour.

November 2021

Bottled 25 cases of 375 ml for inclusion in our 12 Days Holiday Boxes (2 - 375 ml bottles of The Abbey per Advent Box).

December 2021

Bottled 17 cases of 375 ml for sales distribution.

May 2022

Made a second batch of Fortified Haskap Dessert Fruit Wine and bottled 42 cases. This wine is very popular at tastings and tradeshows.

Peter distilling our Haskap wine at Great Gido’s Homebrew under Mark Holinaty’s supervision. Much appreciation to Mark for allowing us to use his facility for the Haskap eau-de-vie.

Kinlochaline Fortified Black Currant Dessert Fruit Wine 19.5% (August 29, 2022)

We have expanded our fortified line with the addition of Kinlochaline Fortified Black Currant Dessert Fruit Wine, also at 19.5% alc/vol.

Made in similar style as The Abbey, again we turned to Great Gido’s Homebrew and the assistance of Mark Holinaty to create another batch of Eau-de-vie, which was expertly blended with our Premium Black Currant (MacAngus) wine. Sweetened just enough to capture the dessert character and accent the Black Currant flavours and aroma.

Kinlochaline Fortified Black Currant Dessert Fruit Wine 19.5% alc/vol is an elegant flavourful wine, with a developed aroma, integrated alcohol and packed full of Black Currant goodness. A little bit earthy, yet smooth and silky, this wine can be enjoyed as an elegant dessert or fine aperitif.

Bottled in 375 mL, with top-of-the-line classic T-caps and security seals for your peace of mind. ~500 bottles or 200 L per batch. This will be a repeat blend in the very near future and is proving to be very popular!

ARGYLL CHERRY ESTATE SELECT FRUIT WINE 12.5% alc/vol (September, 2022)

Prunus x kerrasis or “Dwarf Sour Cherries” - These hybrid Cherries are 75% P. cerasus and 25% P. fruiticosa and named after Dr. Les Kerr from the Ag Canada Morden Research Center who first crossed them.

Saskatchewan’s Dwarf Sour Cherries were further developed at the University of Saskatchewan by Dr. Bob Bors with over 50 years of breeding. They were bred specifically for our Northern climate extremes, and they make excellent wine and liqueurs. There are several varieties of Dwarf Sour Cherries, including the Romance Series (Romeo and Juliet, Valentine and Cupid), Carmine Jewel and Crimson Passion.

Our Winemaker, Margaret, has been busy collecting her Carmine Jewel Cherries over the past few years. Her 4 trees in the front yard produced enough this year to make a small batch of Cherry wine. The colour is fabulous and the flavour is splendid.

The process: Over the first week, Margaret took about three quarters of the frozen Cherries and steamed the juice from them. The rest were crushed to allow fermentation of the juice on the crushed fruit to release the extra aroma and flavour from the skins. The yeast is a slow brewing specialty, and the usual protocols for fermentation of fruit were followed.

Over 4 days of fermentation, the wine was then pressed from the crushed fruit and pumped into the tank. The fermentation proceeded more slowly thereafter, taking 3 full weeks to completion.

This batch was aged for nearly 6 months in tank and will be bottled in early March for a spring 2023 release.

2024: Further Carmine Jewel Cherries were purchased from trusted Saskatchewan growers and fermented to a beautiful wine, that ages well in bottle. Ravensfield is no longer producing cherries (frost got most of them!)