Winemaker Notes: Wine Production Process Design

Please note all design elements and information given is copyrighted c. 2019 Margaret MacInnis

One requirement to obtaining our manufacturer’s license is to submit a Process Design folder which outlines the steps we will be taking to make wine. The information below is part of our Policy and Procedures and is meant to detail (without going into winemaker specifics) the various steps required to produce a top quality wine.

Introduction to Wine Production Process Design

Winemaking is a biochemical process that has evolved for many thousands of years. In its most basic form, yeast catalyzes a series of reactions to ferment the sugar from the input products resulting in ethanol in the wine and carbon dioxide which escapes to the air. The main processes include: harvest or obtain fruit, fruit crush, amend and chaptalize, fermentation resulting in ethanol/wine, correct chemically while settling and stabilizing, rough filter, stabilize again/correct/tank age and, ultimately, package/sterile filter, (store and age) and deliver to the customer.

Significant instability often occurs during the production of wine. Control strategies will be implemented such as input of quality products (fruit, sugar, yeast, amendments), specific lab testing/analysis of individual components and processes with adjustments (including monitoring of temperature, bacterial contamination, adequate fermentation progress, taste and appearance, among others.)

Introduction to Wine Production*

The wine production system is complex because of the number of sequential and parallel biochemical and physico-chemical reactions. In its most basic form, production of wine/ethanol can be represented by the chemical formula:

C6H12O6 ====> 2(CH3CH2OH) + 2(CO2) + Energy (which is stored in ATP)

*yeast* These reactions occur in the yeast cells during fermentation, releasing products

In simplest layman’s terms:

Sugar is digested by yeast ====> Alcohol + Carbon dioxide

(Glucose & Fructose) (Ethyl alcohol or Ethanol) (Carbon dioxide released to air)

Before fermentation begins and during fermentation/stabilization, steps need to be implemented to create a quality product (wine) which will be marketable, palatable, safe, and fall within the parameters of acceptable ABV (alcohol by volume) and food safety as outlined by SLGA and CFIA (Saskatchewan Liquor and Gaming Association and Canadian Food Inspection Agency).

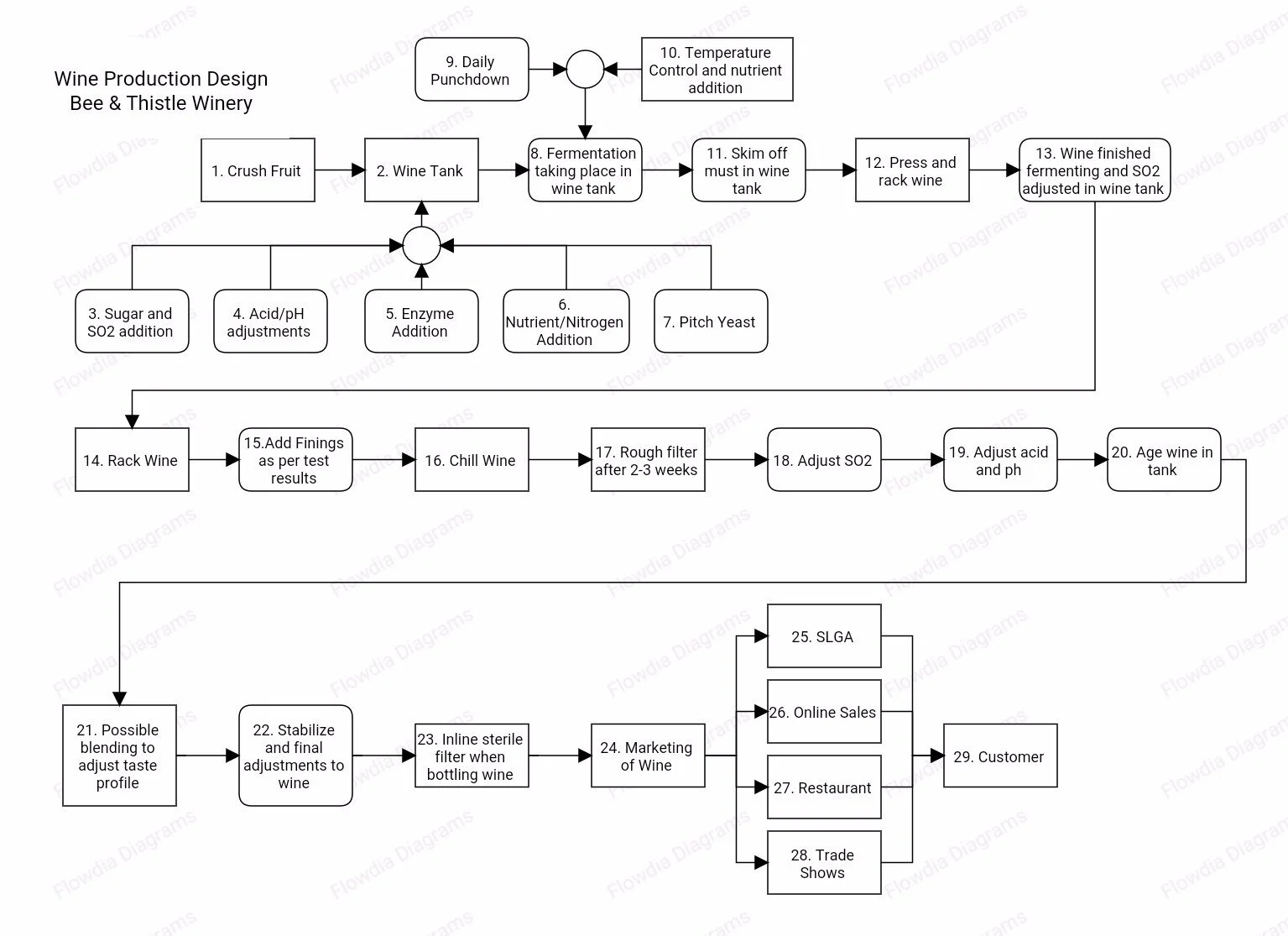

Method of Wine Production From Flow Chart

The flow chart indicates each of the major steps from crushing the fruit to wine reaching the customer. This is the ideal wine production design module. At all stages, adequate cleaning and sanitization of equipment is assumed, which is a process in and of itself.

*please note that chemical terms (such as SO2) are subscripted in technical materials